Evaluating Completed Screen Exposure Test

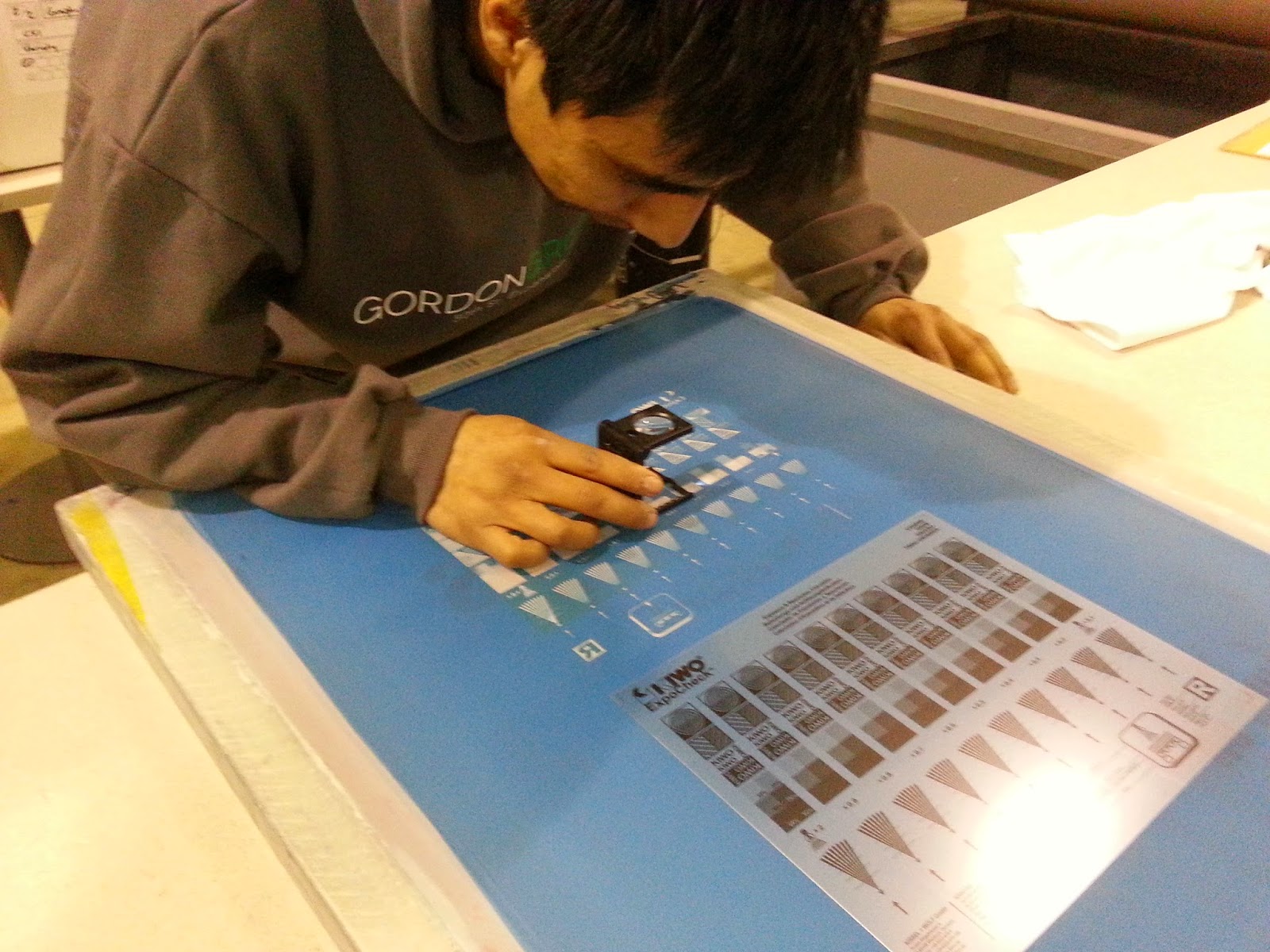

Say, what's this guy doing you might ask?

We'll, that guy is Felipe and he is one of TerrificT's resident screen-print guru's.

What Felipe is doing is reviewing a Screen Exposure Test with what we printers call a 'Loop', which magnifies small details such as halftone dots.

You see, being...